Custom Sand Casting Cast BBQ Barbecue Cast Iron Cooking Grill Grate

Customized Made Productive Technology: Clay Sand Casting, Shell CastingMaterial: Ductile Iron/Gray Iron/ Brass/Bronze/ A

Basic Info

| Model NO. | XINGHE or OEM/ODM |

| Type | Clay Dry Sand |

| Casting Method | Directional Crystallization |

| Sand Core Type | Resin Sand Core |

| Machining | CNC Machining |

| Surface Treatment | Sand Blasting, Bead Blasting, Polishing, Brushed.. |

| Surface Roughness | Ra12.5 |

| Standard | ASTM |

| Service | Casting, CNC Machining, Surface/Heat Treatment, |

| Casting Process | Clay Sand Casting, Shell Casting, |

| Product Material | Ductile Iron, Grey Iron,Aluminum, Brass, Bronze... |

| Product Weight | 0.05-100kg |

| Lead Time | 25-30 Days |

| Certificates | ISO 9001:2015, IATF 16949, CE |

| Application Range | Mechanical &Agricultural Parts,Automotive Service |

| Casting Tolerances | CT9-CT12 |

| Machining Tolerances | +/-0.01 |

| Supply Ability | 150ton/Month |

| Quality Control | Samples Inspection & Mass Order Inspection |

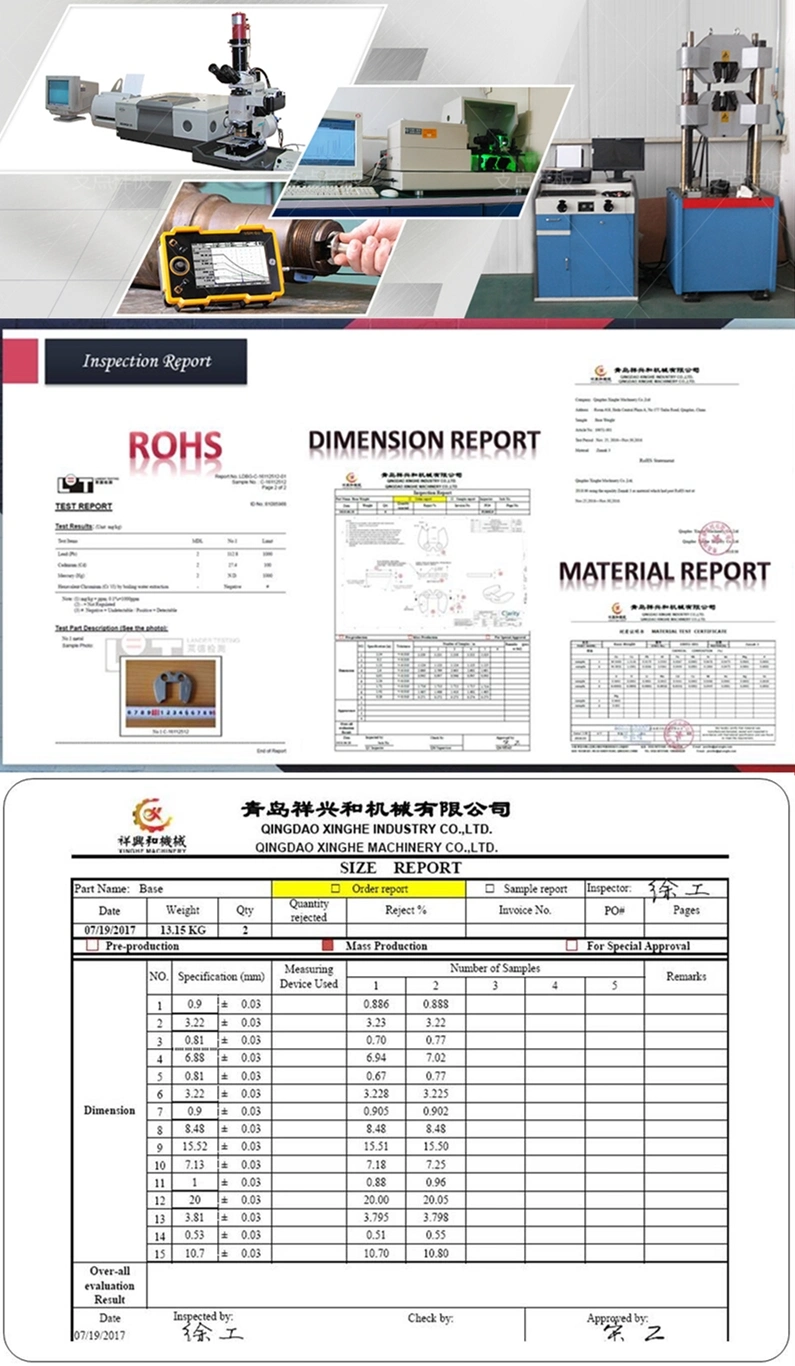

| Testing Report | Size Report, Material Reprot, or You Requests |

| Drawing Format | Step/ Igs/STP/Dwg |

| Payment Term | T/T, Paypal,West Union... |

| Term | EXW/Fob/CIF/DDU |

| Transport Package | Cartons+Pallet |

| Trademark | OEM/ODM/XINGHE |

| Origin | China |

| Production Capacity | 150 Ton/Month |

Product Description

Customized Made

Productive Technology: Clay Sand Casting, Shell CastingMaterial: Ductile Iron/Gray Iron/ Brass/Bronze/ AluminumCasting Tolerances: CT9-CT12 or Machining as Your RequestMachining Tolerances: +/- 0.005mm, ISO2768

Machining facility: CNC,NC lathe,ordinary machine tools,linear cutting machine, NC milling machine, polishing machine.Heat treatment:Normalizing/Quenching/Tempering.Surface Treatment: Sand Blasting, Bead Blasting, Polishing, Brushed Polishing, Powder Coating, Galvanized Plating

Production Display

Quality Control

Test facility:spectrometer, tensile test machine,impact tester, hardness test machine,CMM,PT.

In order to ensure the quality of the orders,our independent QC members to carry out strict inspection at each stage:

(1)Incoming material inspection

(2)Inspection of work-in-progress

(3)Finished product inspection

(4)Random warehouse inspections

Packing Instruction

If any interest, please feel free to send below details:1.Drawings showing Dimensions or Tolerances (pdf/ step/stp/igs/dwg format are workable)2.Material3. Quantity for Samples and Mass Order4.Any requirement on Surface treatment/ heat treatment/ packing...

Send to us